Extruded polystyrene STYROPAN XPS ETICS

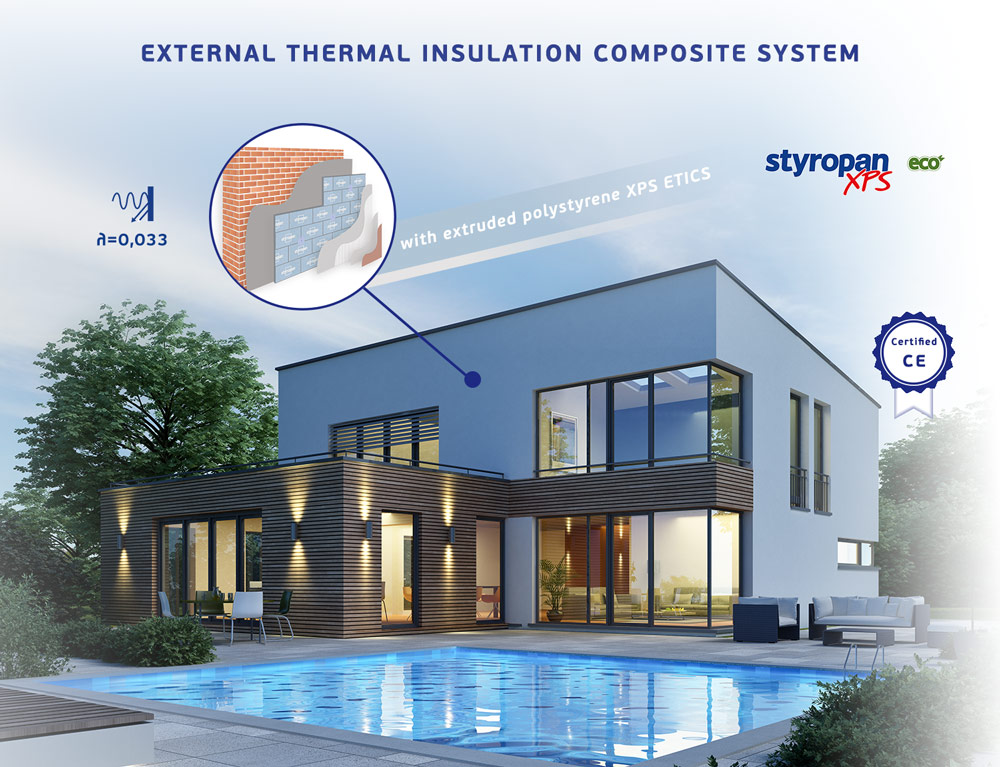

The ideal insulating material for External thermal insulation applications. Whether you are building or renovating your building, choosing Styropan XPS ETICS saves money, as heating and cooling costs are reduced. The property is being upgraded and acquires a higher value of sale or rent while its energy consumption can become even zero (passive buildings, nZEB buildings). You make a reliable investment with a payback period of a few years and ensure thermal comfort.

Exterior thermal insulation (or façade insulation), is the construction solution in which the thermal insulation boards are placed on the outer surface of the building shell.

The thermal insulation boards that are the basic structural element of a thermal facade are placed in combination with other materials that form a Composite Exterior Thermal Insulation System (glue, mesh, plasters, etc.), called ETICS (External Thermal Insulation Composite Systems).

Tα insulating materials which in the form of boards(panels) are used in External Thermal Insulation are extruded polystyrene STYROPAN XPS ETICS , expanded polystyrene Styropan EPS & graphite expanded polystyrene Styropan Graphite EPS.

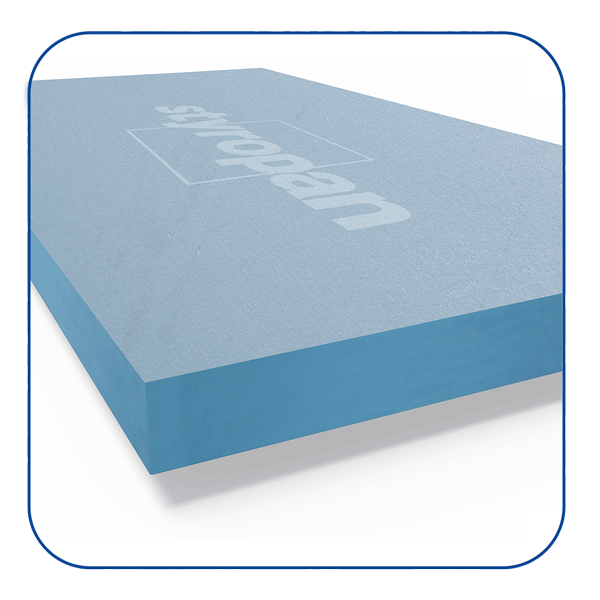

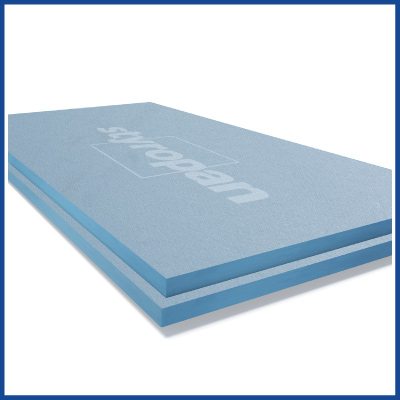

Styropan XPS extruded polystyrene is a foamed, synthetic material, widely known worldwide with many applications in buildings. It is a “closed cell structure” material, which, through polymerization process and continuous extrusion takes the form of thermal insulation panels. Styropan XPS products are eco-friendly as they contain a percentage of recycled raw material.

It stands out for the following features:

- Very low values of thermal conductivity coefficient λ = 0,033

- High mechanical strength

- Very low water absorption

It is available in different types that differ in terms of surface and their proposed applications.

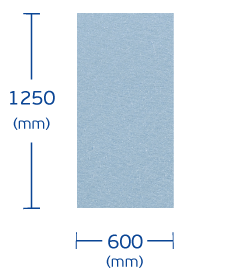

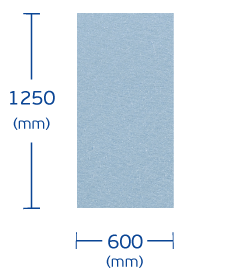

Regarding Exterior Thermal Insulation, the recommended type is STYROPAN XPS ETICS, the boards of which have a "shaved" surface and dimensions of 1.25 x 0.60 meters.

|

Boards of rigid extruded polystyrene foam used in ETICS (External Thermal Insulation Composite Systems), in thermal bridges or as perimeter (base) insulation. Final surface: Extrusion skin is shaved. Mechanical fastening with suitable dowels is also recommended. Dimensions of the boards: 1250 mm x 600 mm. Thicknesses vary from 20 mm to 140 mm, on a step of 10 mm. |

|

Boards of rigid extruded polystyrene foam used in ETICS (External Thermal Insulation Composite Systems), in thermal bridges or as perimeter (base) insulation. Final surface: Extrusion skin is shaved. Mechanical fastening with suitable dowels is also recommended. Dimensions of the boards: 1250 mm x 600 mm. Thicknesses vary from 20 mm to 140 mm, on a step of 10 mm.

|

|

Thermal insulation boards STYROPAN XPS ETICS are CE certified in accordance with the EN 13164 standard. As far as reaction to fire is concerned, they are arranged in E category according to EN 13501-1. |

|

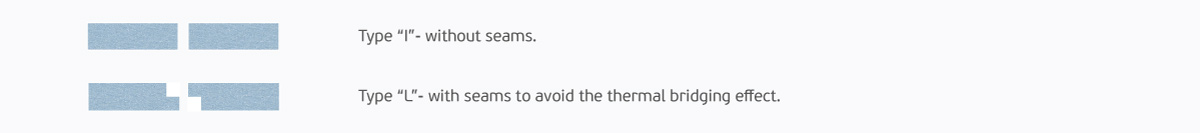

STYROPAN XPS ETICS boards’ edges are shaped as follows: |

|

Extruded polystyrene STYROPAN XPS ETICS boards package info: |

| Thickness d (mm) | Boards/package (items) | Surface/package (m2) |

| 20 | 20 | 15 |

| 30 | 14 | 10,5 |

| 40 | 10 | 7,5 |

| 50 | 8 | 6 |

| 60 | 7 | 5,25 |

| 70 | 6 | 4,5 |

| 80 | 5 | 3,75 |

| 100 | 4 | 3 |

| 120 | 3 | 2,25 |

| 140 | 3 | 2,25 |

*We offer STYROPAN XPS ETICS thermal insulation boards in other dimensions upon order.

|

XPS ETICS

Exterior thermal insulation is the main insulation method to improve the quality of life in your home, to see the electricity bills significantly reduced, to spend your time and your children in a thermally comfortable winter-summer environment, to get rid of from moisture-mold and damage and get an upgraded property with higher value of sale-rent and with low environmental footprint.

Styropan exports its STYROPAN XPS ETICS boards in many countries worldwide. If you are interested at becoming part of our network please contact us at info@styropan.gr